Why 3D Printing Is Still Highly Viable in 2026

Despite periodic claims that 3D printing is “overhyped” or “past its peak,” the reality in 2026 tells a very different story. Additive manufacturing has matured, diversified, and quietly embedded itself into industries that value speed, customization, and resilience. Rather than fading, 3D printing has become more practical, more profitable, and more essential than ever.

1. 3D Printing Solves Real Problems—Not Just Prototypes

In its early years, 3D printing was often associated with novelty or rapid prototyping. Today, it plays a critical role in real-world production.

Manufacturers now rely on 3D printing for:

- Low-volume and custom manufacturing

- Replacement parts and legacy components

- Tooling, jigs, and fixtures

- End-use components in aerospace, automotive, and healthcare

By eliminating tooling costs and long setup times, 3D printing fills a gap that traditional manufacturing still struggles to address efficiently.

2. Customization Is No Longer Optional

Consumers and businesses increasingly expect personalized products. From medical implants to consumer electronics enclosures, one-size-fits-all manufacturing is losing relevance.

3D printing excels at:

- Mass customization without retooling

- On-demand production

- Iterative design improvements

In 2026, customization is not a luxury—it’s a competitive advantage, and additive manufacturing delivers it better than any other method.

3. Supply Chain Resilience Drives Adoption

Global disruptions over the past decade exposed the fragility of centralized manufacturing. Companies are now prioritizing local, flexible production.

3D printing enables:

- Decentralized manufacturing

- Faster response to shortages

- Reduced dependency on overseas suppliers

- Digital inventory instead of physical stock

This shift toward distributed manufacturing makes 3D printing a strategic asset, not just a technical tool.

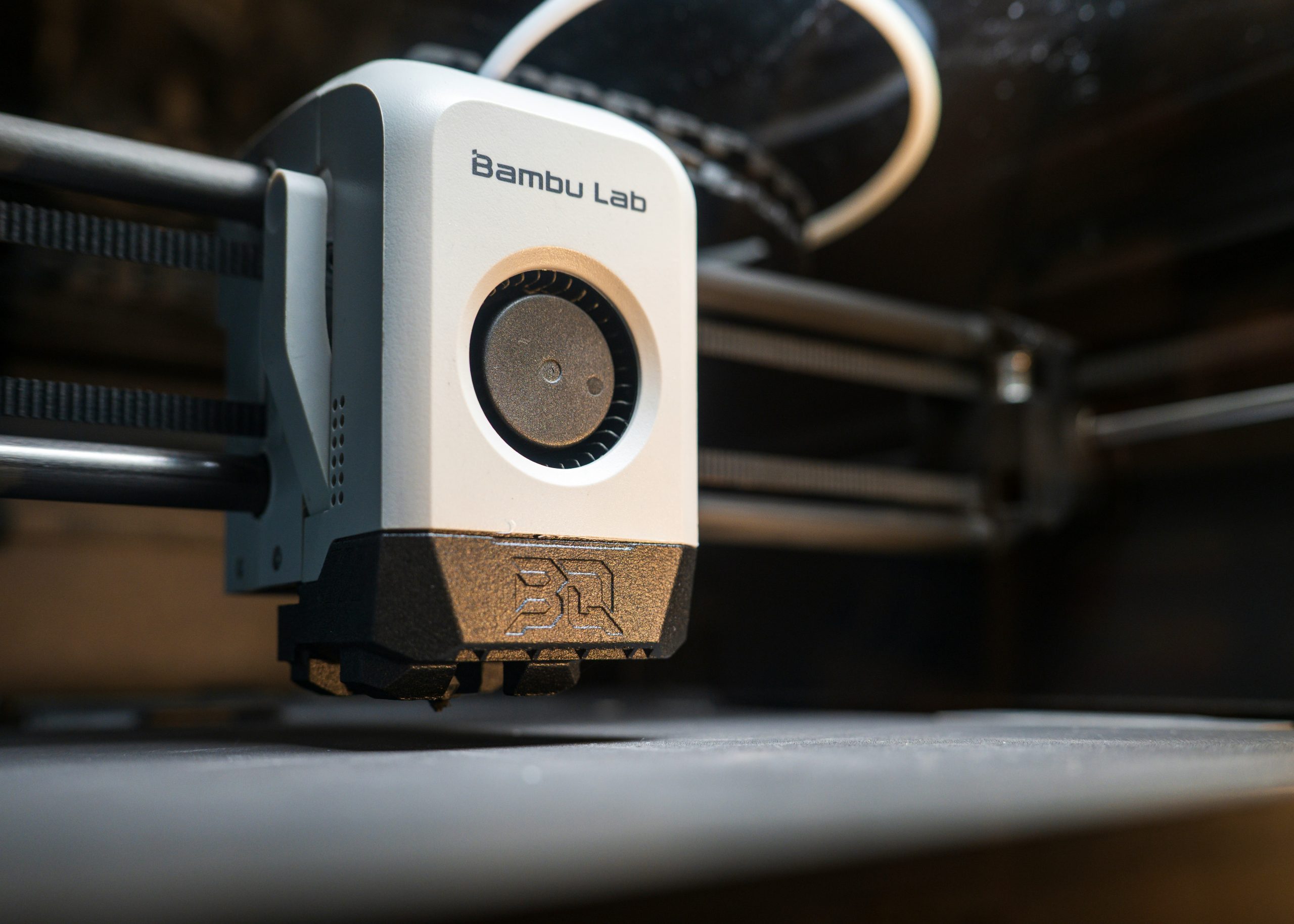

4. Material and Technology Advancements Continue

The viability of 3D printing in 2026 is reinforced by significant advances in:

- High-strength polymers

- Engineering-grade resins

- Metal additive manufacturing

- Multi-material and composite printing

Print quality, strength, and consistency now meet or exceed traditional methods in many applications. Faster machines, smarter software, and AI-assisted optimization have also reduced failure rates and operating costs.

5. Cost Efficiency for the Right Use Cases

While 3D printing is not meant to replace mass production, it is cost-effective where it matters most:

- Short production runs

- Complex geometries

- Lightweight structures

- Rapid iteration

By reducing waste, tooling expenses, and time-to-market, additive manufacturing delivers measurable ROI when used strategically.

6. Sustainability and Waste Reduction

Sustainability goals are shaping manufacturing decisions worldwide. Unlike subtractive methods, 3D printing uses material only where needed.

Key sustainability benefits include:

- Minimal material waste

- Lighter parts that reduce energy consumption

- Local production that cuts transportation emissions

- Recyclable and bio-based materials

In 2026, environmental responsibility is no longer optional—and 3D printing aligns naturally with greener manufacturing practices.

7. Expanding Small Business and Entrepreneur Opportunities

3D printing has lowered the barrier to entry for manufacturing. Small businesses can now:

- Compete with larger firms on innovation

- Launch niche products without massive capital

- Offer specialized services such as custom parts and repairs

This democratization of production keeps the industry vibrant and continuously evolving.

Conclusion

3D printing in 2026 is no longer about hype—it’s about practical impact. It thrives where speed, customization, resilience, and efficiency matter most. As materials improve, costs decline, and industries adapt, additive manufacturing remains not only viable but indispensable.

Rather than replacing traditional manufacturing, 3D printing complements it—filling critical gaps and enabling possibilities that other methods cannot. For businesses willing to use it strategically, 3D printing continues to be a powerful and future-proof investment.

Share this content: