TPU Filament – Material Overview

At Print Layer UK, TPU (Thermoplastic Polyurethane) is used for applications requiring flexibility, elasticity, and high impact absorption. TPU is a rubber-like thermoplastic elastomer that combines the durability of plastic with the flexibility of rubber, making it ideal for components that must bend, compress, or absorb vibration without permanent deformation.

TPU is selected for parts where mechanical flexibility, abrasion resistance, and resilience are critical. Its elastic properties allow printed components to withstand repeated flexing and impact while maintaining structural integrity.

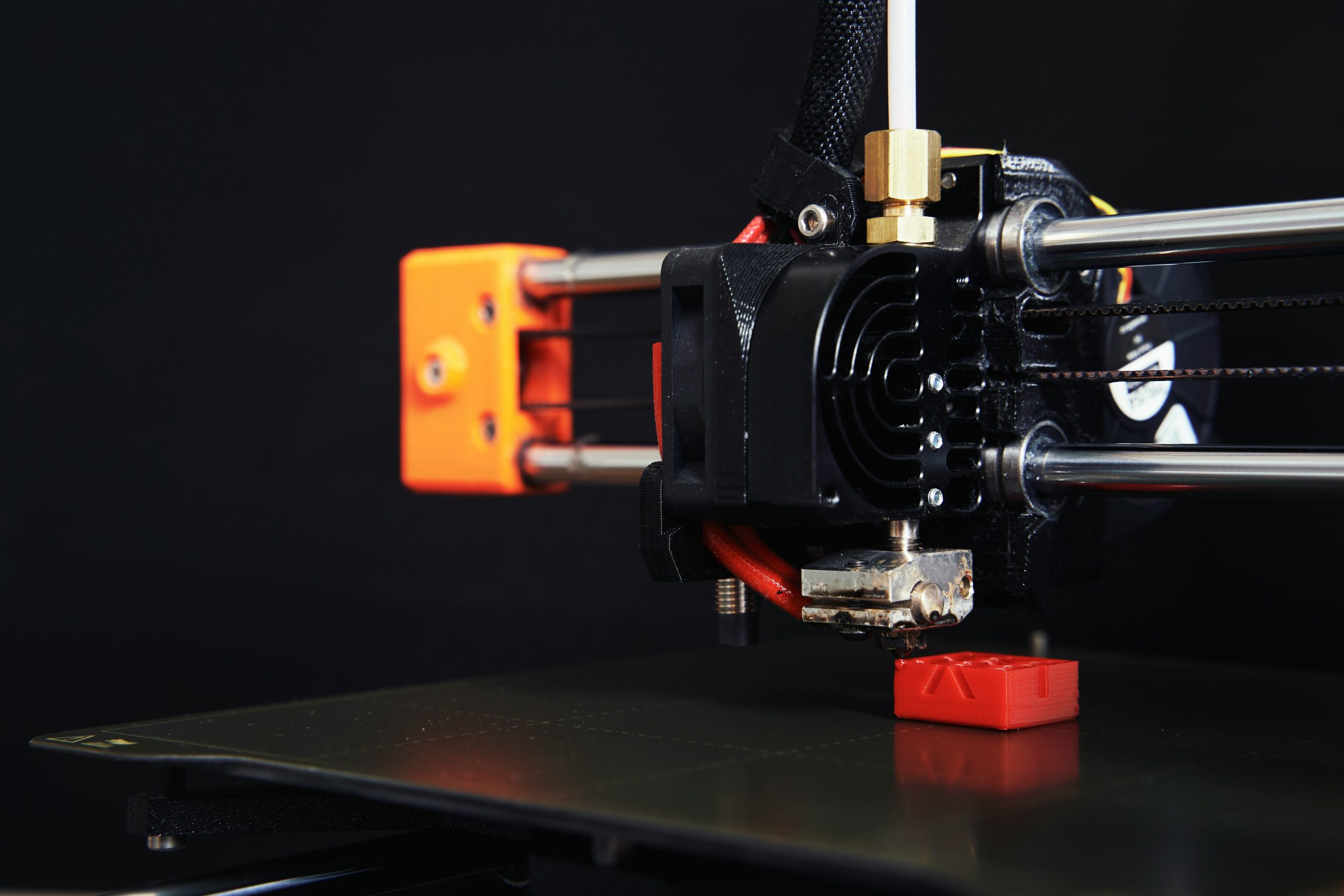

From a manufacturing perspective, TPU requires controlled extrusion speeds and carefully tuned print profiles to ensure consistent flow and accurate geometry. When printed correctly, TPU provides strong layer adhesion and excellent fatigue resistance.

Technical Characteristics

- High flexibility and elasticity

- Excellent impact and vibration absorption

- Strong layer adhesion and tear resistance

- Good abrasion and wear resistance

- Chemical resistance to oils, greases, and many solvents

Typical Applications

- Flexible mounts and brackets

- Protective covers and bumpers

- Gaskets, seals, and shock-absorbing components

- Cable guides and strain-relief parts

Material Limitations

TPU is softer than rigid thermoplastics and is not suitable for parts requiring high structural stiffness or precise sharp edges. Print times are typically longer due to reduced extrusion speeds. TPU also has lower heat resistance compared to rigid engineering plastics.

Print Layer UK Quality Notes

All TPU parts produced by Print Layer UK are printed using optimised, low-speed profiles and calibrated equipment to ensure consistent flexibility, accurate dimensions, and reliable layer bonding. Due to the elastic nature of TPU, slight surface texture variations may be present and are normal for FDM 3D printing.

Share this content: